At the Royal Mint in the U.K., near a building where billions of British coins are made each year, gold is now being harvested from electronic waste.

“It’s essentially urban mining,” says Inga Doak, the Royal Mint’s head of sustainability. “We’re mining from a waste product and realizing the value of the material within it.”

The mint also plans to continue to source some traditionally mined gold, at least for the foreseeable future. But “we wanted to start to shift the dial and actively increase our sourcing of recycled feedback,” Doak says, “which means we could decrease our reliance on more traditional forms of mined gold.”

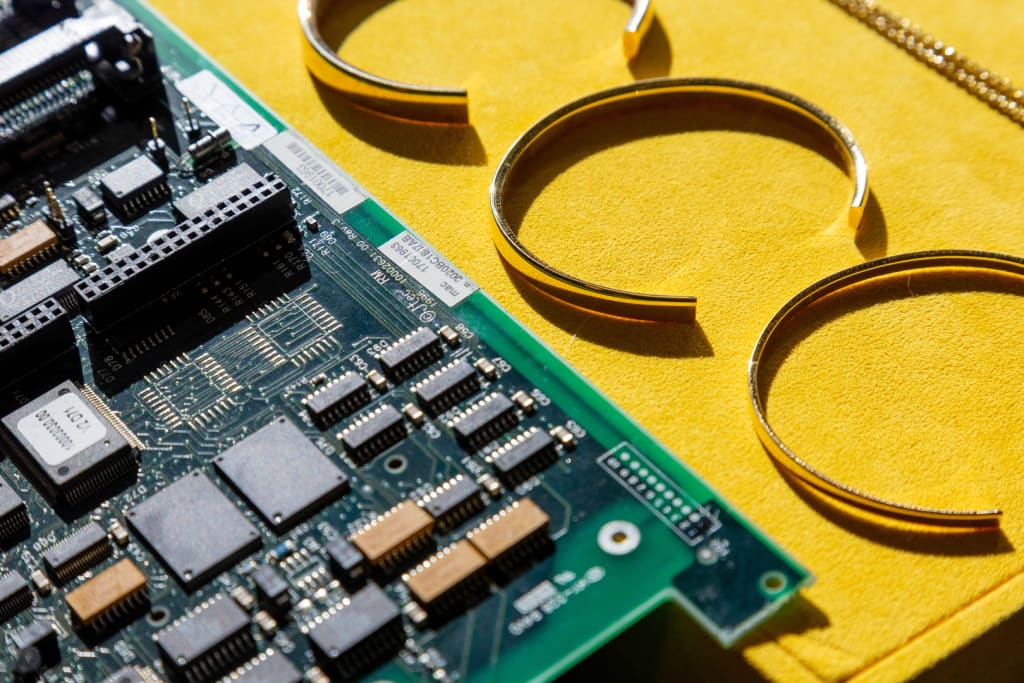

By one estimate, as much as 7% of the world’s gold is sitting in old e-waste. (The material is a key part of printed circuit boards for several reasons, including the way it conducts electricity.) One ton of electronic waste can have roughly 100 times more gold than a ton of gold ore.

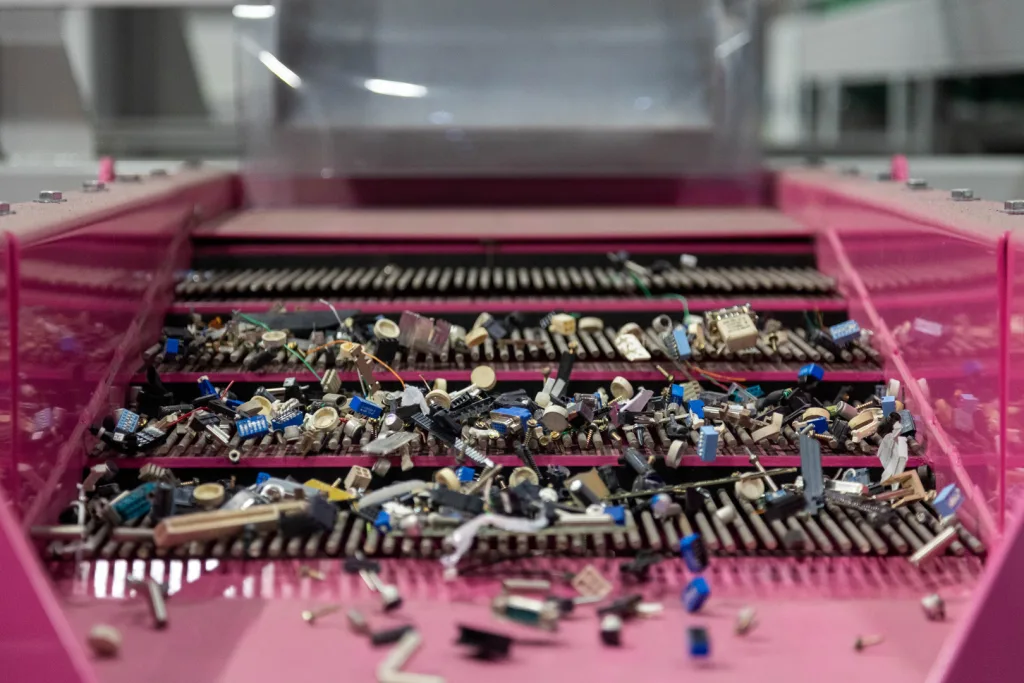

At a new factory, machines break down old circuit boards, and the parts filled with gold are sent to a chemical bath that pulls out the precious material within minutes. The technology, a patented system designed by a company called Excir, is more sustainable than typical recycling.

“The key element is that we can recover that gold at room temperature,” Doak says. That means that the process uses far less energy than other alternatives. (The new factory also avoids shipping e-waste overseas for recycling, which is what happens to most old phones and computers in the U.K. now.) The gold that’s filtered out looks like a powder, and can then be heated up to turn into a shiny, high-purity nugget.

Each year, the factory will be able to process as much as 4,000 metric tons of circuit boards, producing nearly 1,000 pounds of gold, worth about $34 million at current prices.

The Royal Mint doesn’t need gold for people’s change anymore, of course, but it is using the gold first to make a line of jewelry, and then could also use it for products like commemorative coins. The project is part of the evolution of the business: While the Royal Mint has been making coins for more than a millennium, the move to digital money means that fewer coins are needed. The mint has been focusing more on collectible coins, and started considering how to innovate with gold.

“Precious metals are really integral to our history,” Doak says. “So we started to think about how we source and use gold, for instance. How do we retain our skilled workforce from the circulating coin division but utilize them in other parts of business?” When the mint’s overseas currency division closed earlier this year, all 230 workers got new jobs at the company, including at the new gold recycling plant.

The Royal Mint is now working with partners to find uses for the other materials in circuit boards, including copper and aluminum. The plastic may be turned into a powder that can be used as a construction material. The mint also plans to work with other organizations to replicate the gold recycling plant at locations around the world.